Things have changed in the auto parts distribution scene over the last few years. Jobber stores have been hit by mass amounts of disruption to the way business has traditionally been done, faced supply challenges and are looking ahead at a pathway that leads to more e-commerce.

And facing the brunt of all these changes are the store’s counter professionals, the unsung heroes. They are the first point of contact for customers, the ones who navigate the complexity of an inventory that is only growing to find that elusive par. They are the faces that represent the store’s brand. Yet, despite their pivotal role, those in such positions are at risk of their voices going unheard.

This oversight can be a costly mistake for jobber store owners.

Listening to front-line staff, particularly counter professionals, is not just a matter of courtesy — it’s a strategic imperative. These employees have a unique vantage point, seeing firsthand what works and what doesn’t. They understand customer pain points, the inefficiencies in the system and where the gaps are.

So Jobber News decided to get their opinions on where the issues are — and where things are working well. The goal here is to tap into the wealth of insights that can help jobbers drive operational improvements and enhance customer satisfaction.

In essence, the act of listening to front-line staff is a powerful tool for continuous improvement. It fosters a culture of inclusivity and respect, one where employees feel their contributions matter. This, in turn, can lead to lower turnover rates, higher productivity and a more loyal customer base.

So let’s dive into what our survey found…

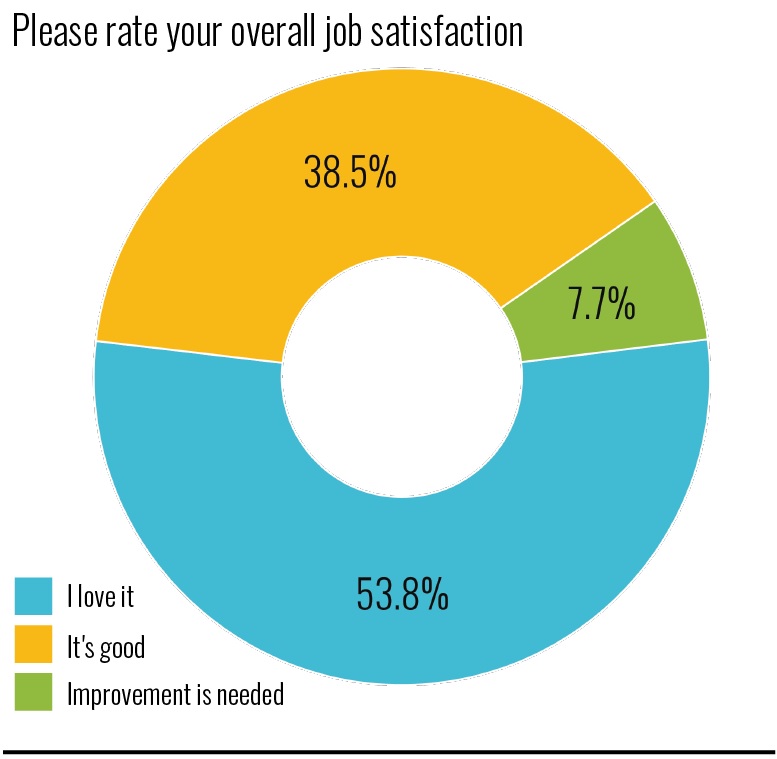

Counter pros love their job

The vast majority of counter professionals are happy with the position they’re in — 92 per cent said that their job is at least good. Breaking that down, 54 per cent said they love their job. Only 8 per cent believe improvement is needed.

“I enjoy learning about new technology in vehicles, the new EV vehicles [are] exciting,” one respondent wrote when given the opportunity to explain their answer.

They admitted that they’ve had challenges being good at customer service but have grown into the role.

“I think I would like to see more training for products we sell in order to better explain the benefits to customers,” they noted as something that could use improvement.

When looking at the other responses, most pointed to the joy of working with customers to find the part they need or otherwise helping a customer resolve the issue they’re facing.

“Love being able to find parts to fit our customers’ needs,” one respondent said.

“Interesting field of work. Making customers happy is satisfying,” another said.

One pointed to enjoying the challenge of the work because there’s a new one popping up all the time. “It feels good to help people solve their problems or just give them helpful advice,” they added.

When it comes to the bad, some pointed to demands of some customers as taking the wind out of them.

“The mental demand to fill the needs of the consumers and installers can be taxing,” one noted.

Another pointed to the lack of pay for a position that requires them to be at least a semi-expert in the field. This respondent prefers to work with pros who know what they’re talking about. “Fulfillment comes from my shop and fleet customers. I help them get what they need without having to explain how to do [a] brake job,” they explained.

Great work environment

The vast majority of counter pros (85 per cent) said they love their work environment and feel supported by their employer and superiors.

“They are constantly trying for improvements, internal, inventory, delivery,” one person noted.

“My employer allows me flexibility to take care of the customer and make the situation right if something goes wrong,” another wrote. “They provide just enough pressure to ensure that we are on the right track, and doesn’t micromanage.”

Many responses were similar, noting that the store feels like a family environment.

“We laugh. We cry. We fight. We make up. It’s like family and we all care,” one commented.

However, another pointed out that even though they feel like a number to the owner, they get along great with their immediate manager.

“The employer is good at providing for employees in pay and benefits,” another respondent said. “Communication from the top down could use improvement.”

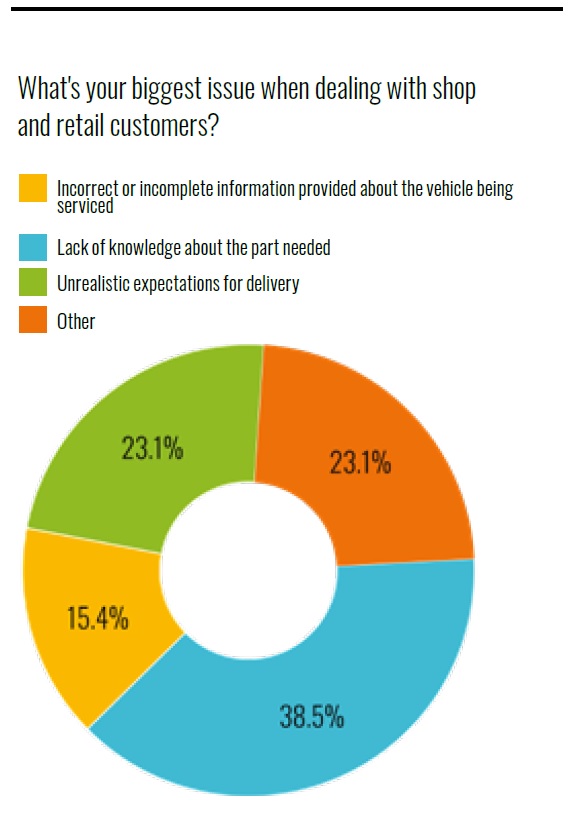

Top customer issues

Dealing with customers can be a challenge. They come from all walks of life and armed with different demands and expectations.

Given the digital age in which we live, that can help — and hurt.

“I find the retail customer is more informed these days but not with the best information most times,” one counter pro mentioned.

Sometimes, the customer doesn’t even know the type of vehicle they’re driving. That doesn’t help when trying to find the parts they’re looking for, one answer pointed out.

But it’s not just the retail customer giving headaches — shops are often making things more difficult on jobber store staff. Many pointed to the lack of information provided about the vehicle being worked on.

“More shops need to use VIN scanning and decoding to get accurate parts,” one respondent commented.

Others noted that their customers often “have no idea” what they’re looking for. The counter pro is left asking many questions about what they’re looking for.

“Providing full information has always been the weaker point for installers and consumers. Lack of knowledge of part needed is also a challenge since OEM manufacturers are creating new part names for their components,” one observed.

Supply issues easing but some complaints

We’ve come a long way from the times of shelves being relatively empty. Jobbers reported selling out of many products; quality wasn’t a question because shops wanted to get their hands on whatever they could to service customers’ vehicles.

Recovery has taken place as 85 per cent of respondents reported that they have most items back in stock or can quickly get what’s needed.

But when asked to comment on how things are, rather than singing praises, counter pros noted there are still challenges they’re facing.

“Still problems with getting basic maintenance parts. Our warehouses need to do a better job of stocking really common maintenance parts,” noted one respondent.

“Our supply chain is good but being NAPA, it should be second to none but [that’s not] not the case. I often have to go outside our company to find product for my customers,” another explained.

A pair of comments pointed to the need for better data when looking up parts online, from fitment data to inventory levels.

One noted that manufacturers are putting products online to be purchased at a lower cost.

“Manufacturers should be more proactively protecting the integrity of the authorized supply chain and authorized reseller network,” they said.

Dealing with online retailers

Speaking of selling online, a common issue jobbers face is when a customer pulls out their phone and sees the same part available through an online retailer for a lower cost. How do they deal with this?

One survey participant noted that they lose many customers to online retailers. But they’re mostly retail customers — shops need reliable parts and service right away.

“We lose lots of customers to online. Retail mostly, Jobber shops need service now.”

“Customers need to realize that there is more than price involved. We offer knowledge and a genuine attempt to help solve problems and issues that seem to happen regularly,” one professional explained.

That answer was the general theme of many others.

“We discuss the warranty issue with buying parts online and how it may cause extended downtime if there is an issue. We don’t try to price match. I don’t feel we need to do anything different,” one said.

“If online they don’t care about quality or brand as much so it is a hard sell but possible if we have time to explain the benefits of our products, service and warranty,” echoed another.

“We warn them that online has negative implications for warranty, support, and accuracy of parts fitment,” one respondent noted. “Online can be counterfeit, used, bait & switch, or other sub-par performing parts.”

Vendor support

Vendors are key to the jobber business. Not only do they supply the product, but they also train staff on the features and benefits. So when the shop calls or a customer walks in looking for advice, the counter pro is ready to serve.

However, responses were hit or miss when it came to what value the vendors provided.

“Reps are thing of past,” one observed. “Most lack technical skill and most have never worked inside a shop.”

There was also biting comment about the lack of training provided, with one in particular saying it was lacking from even just five years ago. Another noted that visits from reps have trailed off since the pandemic era and haven’t rebounded.

“Training is woeful, both from our company and our supplies,” said another.

Transitioning to the more positive remarks, one noted that training was limited, but “most supplier partners have good local representation.”

Others noted that reps do still come by nut as often anymore.

And there were several kudos given as well.

“Local suppliers have done an excellent job keeping up with the changes in our industry, especially during the COVID recovery days,” one said.

“Our suppliers are top-shelf,” another commented.

The challenges

The lack of staff and talent shortages were the clear-cut top challenges for counter professionals (62 per cent)

E-commerce (23 per cent) and supply chain (15 per cent) rounded out the top three

“Automotive aftermarket has done a poor job recruiting youth. HR does not work with schools,” said one respondent who added that there’s a lack of part time jobs at companies because they’re cutting back a lot.

While some noted that they’re bringing people in, they often have little experience applicable to the parts selling business.

“Hard to find good help. Nobody wants to work or do things right,” lamented one professional.

And the need to find people is getting stronger by the day. “We have a lot of experienced talent that are coming to the end of their careers. The new talent coming is coming along but is currently not learning at a rate needed to replace the retiring talent,” one respondent said.

Other challenges noted included online shopping and competing with those retailers.

“People shop online. Online stores don’t have to deal with support and warranty. They don’t have a brick-and-mortar presence with staff and technical support (overhead). You can’t walk into your local Amazon or Rock Auto and show someone the part you need or compare parts for accuracy,” they wrote.

Another noted the online competition as a challenge but also parts proliferation as another.

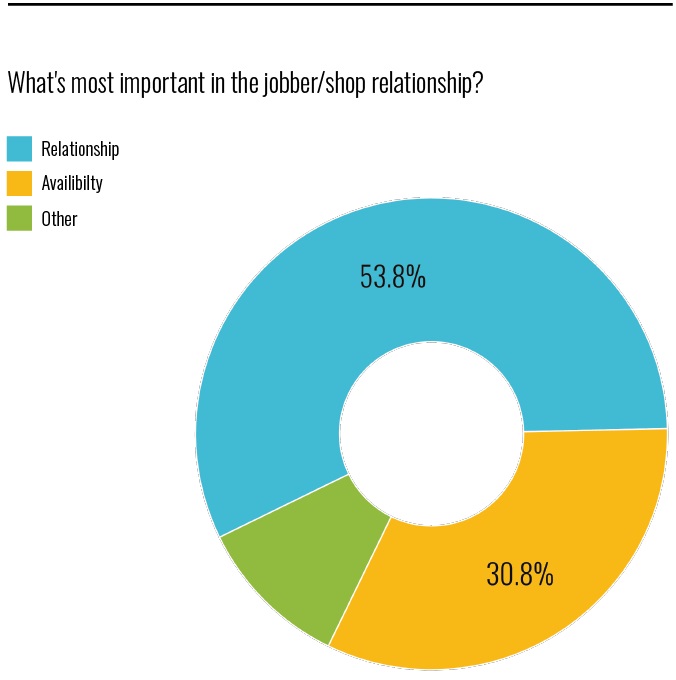

What’s most important

When Jobber News and sister magazine CARS run surveys to shop owners and jobbers, we ask them about what they see as the most important aspect of their relationship. There is no outright consensus — 45 per cent of shops told the 2024 Annual Shop Survey that availability and inventory are the most important factor. Jobbers placed the relationship at the top with 52 per cent saying so.

We decided to ask counter staff the same question. Surprisingly or not, they answered similarly to their bosses — 54 per cent said relationship was tops. A third (31 per cent) picked availability and inventory.

And when given the opportunity to speak to shops, counter pros had plenty of advice to share that would make their jobs easier.

“Acquire and train good front-line talent to handle customer workflow. This will allow your technicians to focus on doing what they do best,” recommended one counter pro.

“Have proper planning and scheduling. Pre-order deferred work parts in advance,” another suggested.

Others noted to be better communicators, support local business and to call the store if you don’t see the product online.

One respondent urged shops to use better parts. “Saves us all time in the long run,” they said.

This article originally appeared in the September issue of CARS magazine

Leave a Reply