Auto repair technicians and service advisors confront new challenges and opportunities in a rapidly evolving industry. We surveyed professionals to understand their views on technology, customer behaviour, and what they need to thrive in their careers

Auto repair technicians and service advisors are the lifeblood of the automotive service industry. As the technological and customer service landscape evolves, so too do their roles.

Today, they grapple with increasingly complex vehicle systems, the growing expectations of informed (and sometimes misinformed) customers and the pressure to continuously upskill.

Technicians and service advisors also see where the challenges lie in the business — by working day in and day out in the bays and at the service counter, they can see the unique issues holding the business back and the successes that need to be celebrated.

To understand their perspective, CARS magazine conducted a survey of these professionals to paint a detailed picture of the challenges they face, the aspects of their jobs that bring them satisfaction what they need from employers and partners to succeed and more. We asked general questions of both groups and also had some specific questions just for techs and advisors.

The hope here is that shop owners will be able to review the findings with the understanding that these responses were provided anonymously and possibly more honestly than if these questions were asked directly to their staff. Ideally, shop leaders can take it as direction for where improvements could be made and where they can build on things that work well.

Of note, we asked the same question we ask of shop owners, jobber store owners and counterpros: What’s most important in the jobber/shop relationship? Techs and advisors answered similarly as their shop owners: Availability (64 per cent).

They like their job

The overwhelming majority (82 per cent) of technicians and service advisors said they at least like their job. Most respondents (45.5 per cent) said they love their job.

“Great owner support, great hours. Most fulfilling is when rare parts are found and repairs are done on time and within quote,” one respondent highlighted.

“I get the relatively immediate satisfaction of knowing whether or not I was successful at a repair,” said another. “Doctors and lawyers may take years before achieving the same on a single case.”

And while others praised their employer for a great working environment, they also pointed to challenges in getting customers to understand the work they do.

“Educating people about their cars, the maintenance required to keep them going, explaining required repairs and what can wait,” one explained as an area that needs improvement.

One echoed this sentiment and noted that when customers have unrealistic expectations, rather than pushing back, shop leadership will add pressure on staff to get the job done in the customers’ desired, yet “unreasonable” time frame.

“What could improve is the customers’ understanding that the jobs take time and often we are booking several days out,” they added.

And for one, they summed up the job like this: “It’s a tough industry to stay with your whole life. It’s a roller coaster of emotions. Super highs and super lows. You have to ride with the punches, stay focused and remain calm. But grass is not greener on the other side. Every occupation has its hurdles.”

But things can change for the better. When asked what could be improved, the answers ranged from more respect from male customers towards female staff to heating in the winter and air conditioning and the summer, tool allowances and medical benefits.

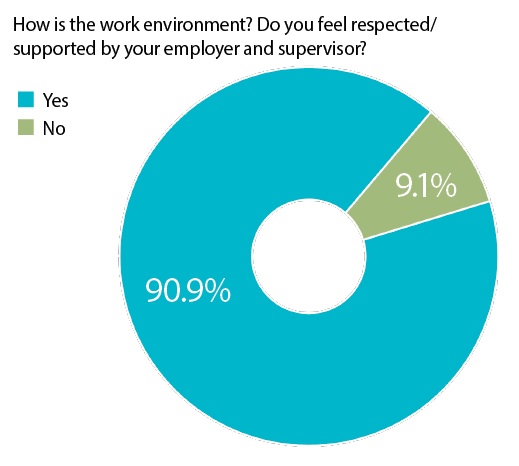

They feel respected, too — more than 90 per cent said so.

“What I like about the employer is that he treats the crew fairly. When something goes wrong it is addressed, corrected and moved on,” one respondent explained. “The employer is good a creating work and ensuring there is a place to come to work to.”

Compensation

To hear some experts tell it, the automotive aftermarket is drastically underpaying technicians and service advisors. Low labour rates don’t allow for growth of the shop, nor attracting talent.

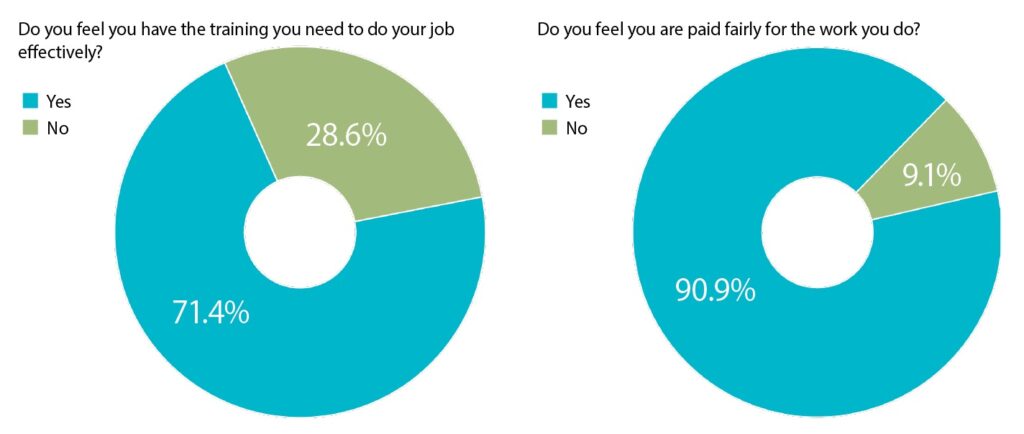

But when we put the question of compensation to our readers, 91 per cent said that they’re paid fairly for the work they do.

“I get paid flat rate. As my productivity is high, I can earn approximately 1.5 times my hourly wage on a regular basis, working overtime is available, and even more lucrative,” one respondent explained.

Another was more or less apathetic: “The pay is what it is. Yes, I would like to make more money but, at the end of the day, our wages are comparable with middle-class working jobs. We are not white-collar workers and should never and will never be compared with doctors or lawyers.”

Another felt they were paid fairly by their employer for the work they do, based on their ability to handle the load.

“The employer is open to change in the wage if needed. If the gap is present, they try to shorten the distance between expected wage and actual wage. If there is a large gap that cannot be closed, then a change may be needed,” they commented.

Service advisor insights

We asked a series of rapid-fire questions to service advisors to get their thoughts on certain topics.

All said they understand how to book the schedule for maximum productivity as well as how to gather the best information to ensure a technician can diagnose a vehicle effectively. All algo agreed that they have enough education on vehicle service to effectively advise clients.

One question where there wasn’t universal agreement was on booking the customer’s next service appointment. A minority (43 per cent) said they do while the rest (57 per cent) said they don’t.

Another was on effectively qualifying clients The majority here (57 per cent) said they have been given the education to do so while the rest said no.

When asked to further comment, advisors praised their shop.

“I feel we are generally doing well, we certainly have become more picky when choosing the work that comes in and the customers we want to work with,” one advisor explained.

Others highlighted that their customer service is tops, training courses have helped — along with years of experience doing the job — and they’ve implemented tools like reminders for appointments and for annual safety inspections.

Technician insights

A series of rapid-fire questions were given to technicians as well. And the results may come as a surprise as they go against what some may see as issues in the industry.

When asked if they have enough training to do their job effectively, more than seven in 10 (71 per cent) agreed with the remaining 29 per cent saying no.

The overwhelming majority (86 per cent) said they have the tools in place to do their job effectively.

“I have most of the tools needed to do the physical work, but access to OEM-level diagnostic systems is often prohibitively expensive for a tech, especially in an all-makes shop,” one technician commented. “A tech may need more than one diagnostic tool platform. Shops should bear some of that cost.”

And all agreed that their employer shares the expectations of the job with them.

The one area where there was some disagreement was when asked if they were given enough time to properly diagnose a vehicle — 57 said yes, 43 said no.

The job of a technician and the role of a shop owner is a tough balancing act, one pointed out.

“If we charged accordingly for our time and got paid what we as technicians are worth, we would have no work because the cost of keeping a used vehicle on the road would be far more costly than leasing or trading in every three years,” one tech observed.

They further explained that costs have to be down and wages suppressed for consumers to keep their cars as long as possible. “This way, we make more money over a longer period of time. It just is the way it is. We do not have to fix every repair on every make and model vehicle. We as technicians should be able to pick and choose our battles.”

Committed to the profession

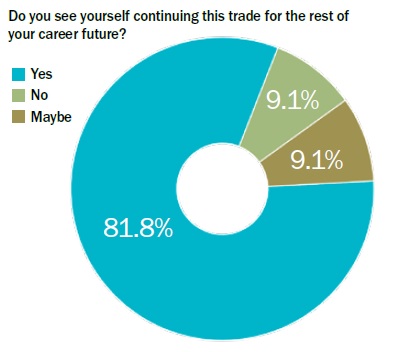

For 82 per cent of respondents, both techs and advisors, they plan to stay in this industry for as long as they can.

For virtually all respondents, it would be a physical issue that would take them away from them job.

“Wear and tear on my body. The older I get the longer it takes to lumber up at the start of the day,” one pointed out.

Another said they would be pushed out because of the lack of respect shown by men to women. “Losing my patience with men who don’t respect a women in the automotive industry,” they wrote.

Another pointed to a variety of reasons. “There are many factors to consider such as employers, customers, the tools needed for basic jobs, the stress caused by the demands of the industry, the loss of the technicians in the field and that causes a vicious circle of overwork.”

Under pressure

For many technicians, the most fulfilling aspect of the job is solving difficult problems. One respondent shared, “I get immediate satisfaction when I see a repair succeed. It’s rewarding to know I’ve made a difference in someone’s day.”

But there’s mounting pressure on them. This is compounded by the rapid pace of technological change in the industry. Keeping up with technology (54.5 per cent) was picked as the top challenge for techs and advisors at work.

One lamented that they’re too far behind the learning curve at the start of each day and it’s difficult to learn as you go.

Another listed everything noted above plus module reprogramming and flashing, theft deterrent systems, CAN bus diagnostics as new tasks to learn.

“Every job is time-consuming, learning how systems work,” they said. “No one can know everything there is to know on every make and model car. It is impossible to get paid for the amount of time learning all this technology.”

Another noted that training is out there — it’s just a matter of finding the time.

“Specific issue I regularly notice is the amount of work to do,” they explained. We are consistently booked 3-4 days out and have more work to do in a day than what seems possible. This is a challenge to keep the jobs moving forward at times.

Concerns about the future

As more advanced systems like ADAS (advanced driver assistance systems), electric vehicles and hybrid vehicles enter the market, technicians must continuously learn and adapt. This is a concern for both groups.

While some are excited about the opportunities that new technologies bring, others worry about the costs associated with staying current. One technician predicted that “this spells the end of the mom-and-pop shop. You need to be at a certain size to afford the tooling and training required for the new technologies.”

Another said they just can’t keep up and they’re frustrated.

“All items will be slowly implemented. Don’t have to fix every repair out of the gate. By the time we figure out and get good at repairing something it’s no longer present and moving on to the next technology. This job is not easy and not for the faint at heart,” they said.

This article originally appeared in the October issue of CARS magazine.

Leave a Reply